Petroleum Engineers Association | Blog | Coiled Tubing: The Backbone of Modern Well Intervention

In today’s oil and gas operations, efficiency, precision, and safety define success. One technology that brings all three together is Coiled Tubing (CT) a continuous length of steel pipe wound on a large spool, capable of being inserted into live wells to perform a range of downhole operations without killing the well.

But what makes coiled tubing such a game-changer? Let’s see

⚙️ What is Coiled Tubing?

Coiled Tubing is a flexible steel pipe typically 1” to 3.5” in diameter mounted on a reel and deployed into a well through surface equipment like the injector head, gooseneck, and lubricator. It allows continuous operations for:

- Well cleanouts

- Acid stimulation

- Nitrogen lifting

- Fishing operations

- Logging and perforating

Unlike conventional jointed tubing, CT minimizes rig-up time and enhances well control saving both time and cost.

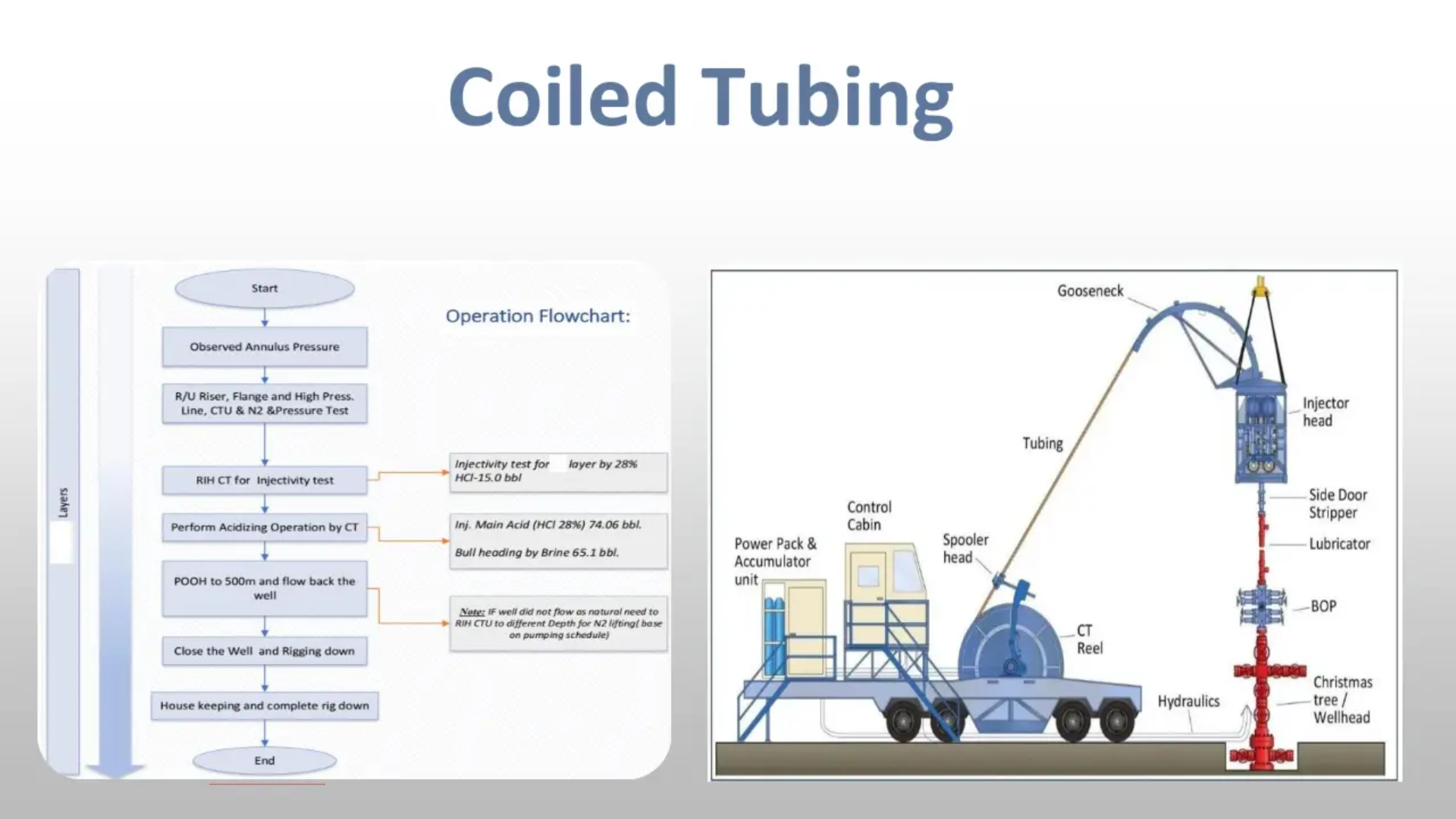

📊 Operation Flow Overview

The flowchart in the image highlights a standard acidizing and injectivity workflow using coiled tubing:

- Observe Annulus Pressure – Establish baseline well pressure and stability.

- Rig Up (R/U) – Connect riser, high-pressure lines, and nitrogen system.

- Injectivity Test – Evaluate formation response using HCl (15 bbl).

- Acidizing Operation – Pump main acid (HCl 28%, 74 bbl) to stimulate production zones.

- Bullhead Brine (65 bbl) – Displace acid and initiate cleanup.

- Flowback and POOH (Pull Out of Hole) – Recover fluids and assess production response.

- Rig Down and Housekeeping – Ensure safe demobilization and post-job reporting.

This systematic approach ensures well integrity, controlled pressure management, and optimized production enhancement.

Coiled tubing operations bring real-time adaptability to well intervention. The ability to circulate fluids, inject chemicals, and mechanically clean the wellbore under pressure makes CT indispensable in both production enhancement and well maintenance.

Moreover, in acidizing and stimulation operations, CT enables precise placement of treatment fluids directly at the damaged zones improving the overall success rate of stimulation campaigns by up to 30–50% compared to conventional bullheading.

With the rise of digital well intervention tools, CT units are evolving fast integrating sensors, downhole telemetry, and automated injector heads to ensure safer, data-driven operations.

As the industry continues pushing toward smart, efficient field interventions, coiled tubing remains at the heart of innovation connecting traditional well engineering with modern digital insights.

To learn more checkout our self paced course on Coiled Tubing: https://www.peassociations.com/e-learning-coursedetails/coiled-tubing-technology-principles-procedures-troubleshooting

Leave a comment on this Blog/Article.