HPHT Operational Practices and Guidelines

| Code | Duration | Currency | Fee Per Person |

|---|---|---|---|

| EL-HPHT-PEA |

15 Hours

|

USD

|

500

|

This is a self-paced, on-demand e-learning course. Upon enrollment, all course videos and materials will be delivered to your email within 12 hours. A certificate will be issued upon successful completion of the required quizzes and assignments.

Boost your team's skills and your budget! Enjoy group discounts for collaborative learning. Send an inquiry to info@peassociations.com.

HPHT Operational Practices and Guidelines

This self-paced course equips drilling and well control professionals with the knowledge and strategies to operate safely and effectively in high-pressure high-temperature environments.

Description

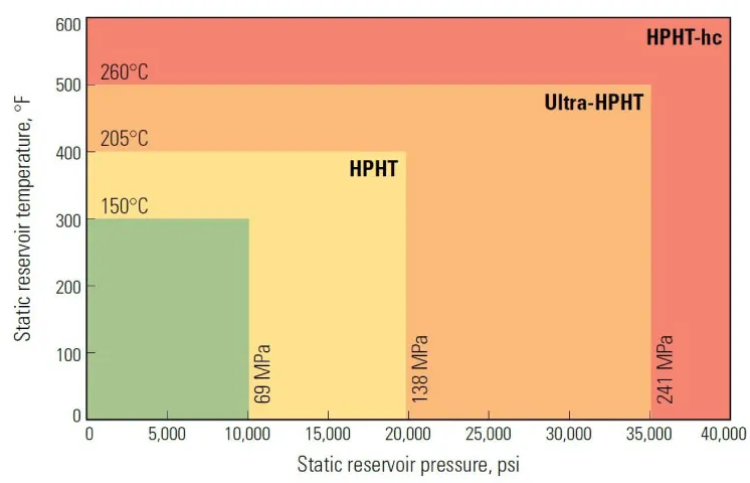

High-Pressure High-Temperature (HPHT) environments present unique challenges that demand advanced operational awareness and precise execution. This course is designed to prepare drill crews, supervisors, and engineers to understand the technical and human factors that influence performance in HPHT wells. Covering topics from pore and fracture pressure windows to well control equipment, gas behavior, and constant bottom-hole pressure methods, the training builds a strong foundation for safe and efficient HPHT operations. Learners will also explore case-based scenarios that emphasize crew discipline, timely decision-making, and effective communication — skills critical to ensuring operational success.

The oil and gas industry continues to push boundaries into deeper, hotter, and higher-pressure formations. Operating in HPHT environments requires more than just technical expertise it calls for vigilance, collaboration, and the ability to manage narrow drilling windows. This course provides the essential knowledge and structured guidelines to help professionals navigate the risks, minimize well control incidents, and support successful drilling operations.

By the end of this course, participants will be able to:

• Describe the differences between conventional and HPHT operations.

• Identify key challenges of working within narrow pore pressure and fracture pressure margins.

• Recognize and respond appropriately to kick warnings and indicators.

• Apply constant bottom-hole pressure methods for well control.

• Explain gas properties, migration, and hydrate formation in HPHT environments.

• Understand the operational limitations of well control equipment in HPHT wells.

• Apply fingerprinting techniques and assess wellbore ballooning impacts.

• Promote crew discipline, communication, and safety culture during HPHT operations.

• Improved well control performance and reduced risk of operational failures.

• Competent personnel capable of handling advanced HPHT drilling challenges.

• Stronger safety culture and communication across drilling and service teams.

• Enhanced readiness to meet industry demand for HPHT-capable professionals.

• Enhance career readiness for HPHT drilling and well control assignments.

• Strengthen decision-making in pressure-critical drilling environments.

• Confidently interpret kick indicators and implement control procedures.

• Build resilience by understanding advanced HPHT operational risks and mitigations.

• Drilling supervisory personnel (senior toolpushers, day/night toolpushers)

• Drill crew (drillers, assistant drillers, derrickmen)

• Office-based staff (superintendents, well engineers, geologists)

• Service hands supporting HPHT operations

• Introduction to HPHT Operations

• Course objectives and scope

• Industry definitions and applications

• Key characteristics and challenges

• Pressure and Temperature Fundamentals

• Pore pressure and fracture pressure concepts

• Maximum Allowable Annular Surface Pressure (MAASP)

• Mud weight windows and kick tolerance

• Human Factors in HPHT Operations

• Crew discipline and communication

• Impact of minor procedural lapses in critical environments

• Well Control Principles

• Causes of kicks and early warning indicators

• Transition zone precautions

• Shut-in procedures and response timing

• Equivalent Circulating Density (ECD)

• Pressure and temperature effects on mud weight

• Impact of flow rate, RPM, and temperature on ECD

• HPHT Procedures

• Pit discipline and flow checks

• Tripping practices and swab/pump-out precautions

• Slugging and inventory requirements

• Well Control Equipment in HPHT

• High-pressure kill assemblies

• Transition zone equipment considerations

• Well Killing Methods

• Constant bottom-hole pressure methodology

• Driller’s, Wait and Weight, Volumetric, Stripping, and Bullheading methods

• Gas Properties and Behaviors

• Gas expansion, migration, and hydrate formation

• Gas behavior in oil-based mud

• Advanced HPHT Considerations

• Wellbore ballooning and supercharging

• Fingerprinting techniques for minimizing kick volume

• Operational checklists for readiness and kick response

On successful completion of this training course, PEA Certificate will be awarded to the delegates

This course has been meticulously developed by a seasoned PEA expert renowned in the oil and gas industry. With extensive hands-on experience and a proven track record in delivering innovative solutions, our trainer brings a wealth of technical expertise, deep industry insight, and a commitment to excellence. Learners can trust that they are gaining knowledge from a leading authority whose dedication to professional development ensures you receive only the highest-quality training to elevate your skills and career prospects.