Oil & Gas Equipment Preservation & Identification

A focused program on maintaining the integrity and traceability of critical equipment from receipt to commissioning and lay-up. The course covers preservation planning, storage and packaging controls, condition monitoring, and robust identification systems that support quality, safety, and audit readiness across the asset lifecycle.

Workshop Objectives

• Build a risk-based preservation plan covering storage, VCI/desiccants, purging, rotation, and periodic inspection.

• Apply acceptance, tagging, and traceability controls linking MTRs/PMI, serials, barcodes/RFID, and documentation.

• Specify coatings, sealing, cleanliness, and environmental controls to prevent corrosion and degradation.

• Define recommissioning, turnover, and records management to ensure compliance and audit-ready evidence.

About the Presenter

Delivered by a senior reliability and materials practitioner with experience in upstream, midstream, and downstream projects. Instruction emphasizes practical preservation controls, traceability discipline, and measurable outcomes suitable for complex facilities and regulated environments.

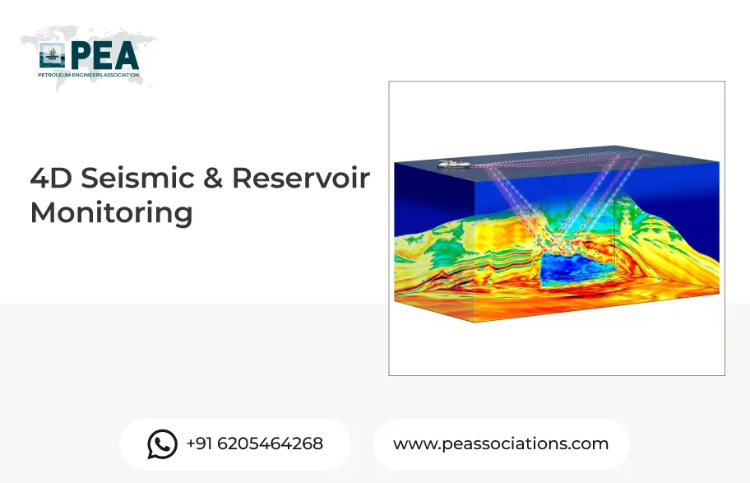

Applied Python for Oil & Gas

This workshop teaches practical Python programming tailored for the oil and gas industry. Participants will learn to automate workflows, manage large datasets, perform petrophysical and production data analysis, and integrate Python with industry-standard software tools. The course emphasizes real-world applications such as reservoir monitoring, production optimization, and data-driven decision-making.